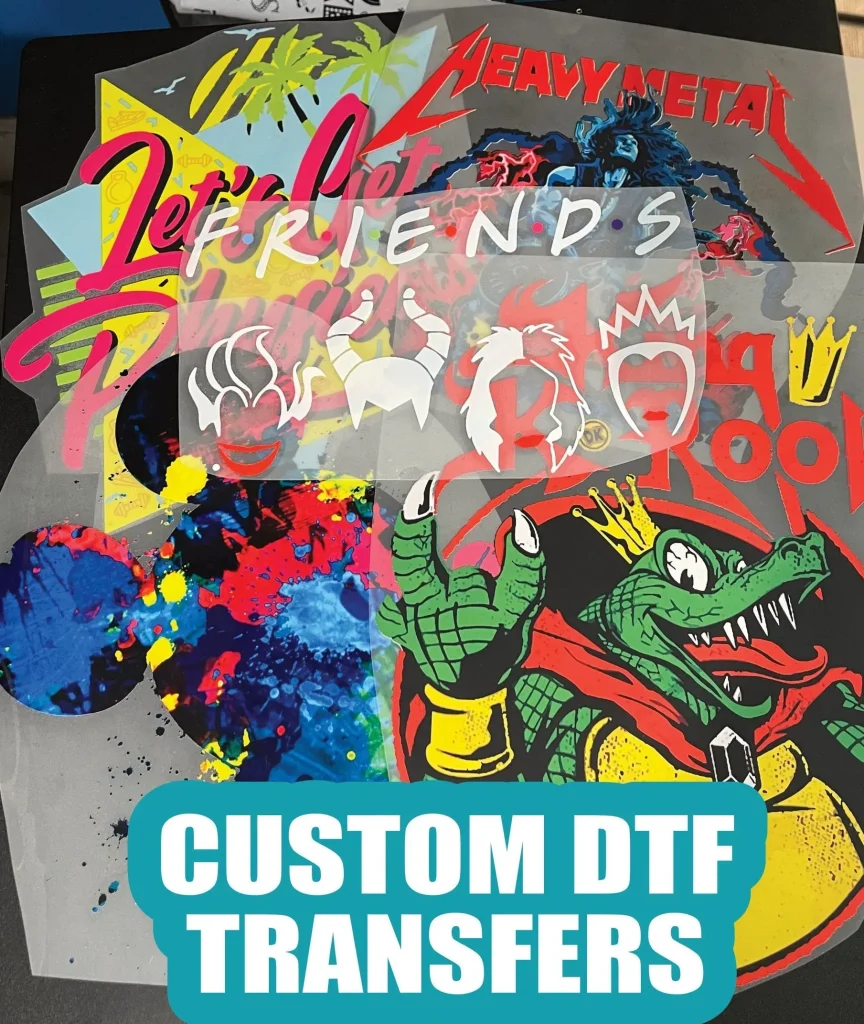

DTF transfers, short for Direct-to-Film transfers, are revolutionizing the custom printing landscape by offering a streamlined approach for both hobbyists and professionals alike. This innovative technique involves printing stunning designs onto a special film, which can then be heat transferred to various fabrics, making it an ideal choice for custom apparel. If you’re a beginner looking to dive into DTF printing, this guide will provide essential insights and tips on how to use DTF transfers effectively. From understanding the necessary equipment to exploring creative possibilities, you’ll gain the knowledge needed to excel in this vibrant field. Get ready to unleash your creativity with DTF transfers and elevate your custom printing projects to new heights.

Direct-to-Film printing, often referred to as DTF printing, has emerged as an exciting method for applying vivid designs onto fabric. This technique allows for intricate detailing and vibrant color reproduction, appealing to both casual crafters and serious entrepreneurs. By utilizing film as an intermediary, users can achieve high-quality transfers that adhere well to various textiles. Whether you’re curious about how to leverage these innovative transfers for personal projects or looking to start a custom apparel business, understanding the essentials of DTF printing is crucial. Explore this dynamic printing style to unlock new creative avenues and enhance your wearable art!

Understanding the DTF Printing Process

DTF printing, or Direct-to-Film printing, is a modern technique that allows for the seamless transfer of intricate designs onto fabric. This process begins with the creation of a digital design, which is printed onto a specially coated film using a DTF printer. The beauty of DTF printing lies in its ability to produce vibrant, high-resolution prints that are durable and withstand repeated washes. The film, once printed, requires the application of adhesive powder, which binds the design to the fabric when heat pressed, making it a favored choice among both hobbyists and professional custom print businesses.

For beginners, understanding the intricacies of the DTF process is crucial. The steps may seem daunting at first—designing, printing, applying adhesive, and heat pressing—but with practice, they become second nature. Each step in the DTF process is designed to ensure that your designs not only look great when applied but also maintain their integrity over time. Moreover, the DTF method is versatile and can be applied to various substrates, including cotton, polyester, and blends, expanding your creativity in custom apparel.

The Benefits of DTF Transfers for Custom Apparel

DTF transfers provide a host of advantages that make them an excellent choice for customizing apparel. One of the primary benefits is the incredible versatility in fabric compatibility. Unlike traditional methods that may be limited to certain materials, DTF can be used on a variety of fabrics, ensuring that your designs can reach a broader audience. Additionally, with the use of quality DTF inks, the prints retain vibrant colors that do not fade easily, enhancing the longevity of your custom designs.

Another significant benefit of DTF transfers is the precision it allows for intricate designs. Detail-oriented custom printing is easily achievable, which is a steadfast requirement for professional results. Coupled with the fact that DTF printing eliminates the need for weeding, the process becomes not only more efficient but also less frustrating for beginners. As you delve into custom apparel creation, these advantages make DTF transfers a compelling option for bringing your creative visions to life.

Essential Equipment for DTF Printing

To get started with DTF printing, you need some specific equipment to ensure a smooth workflow. First and foremost is a DTF printer, specifically designed to handle the unique inks and films required for this method. These printers offer various features, and for beginners, selecting an entry-level model that provides clear and vibrant prints will suffice. Additionally, having high-quality transfer film is essential, as it’s where your designs are first applied and prepared for the heat transfer process.

Another critical component of DTF printing is the adhesive powder, which acts as a bonding agent during the heat transfer stage. It is carefully sprinkled onto the printed design to ensure that the artwork adheres correctly to the fabric when heat pressed. Lastly, a reliable heat press is indispensable—this device applies the necessary heat and pressure to transfer your designs effectively. Investing in quality equipment not only aids beginners but also ensures consistency and durability for custom DTF prints.

How to Use DTF Transfers: A Beginner’s Guide

For those new to custom printing, knowing how to use DTF transfers can open a world of creativity. The process begins by designing your artwork using graphic design software. It is essential to keep your designs high-resolution to maintain quality when printed. Once your artwork is prepared, the next step involves loading the transfer film into your DTF printer and fine-tuning the printer settings to fit your specific design needs.

Following the printing phase, the fun truly begins with applying adhesive powder to the warm prints—this step is crucial for ensuring the design sticks to the fabric accurately during the transfer. After curing the adhesive, you will align the film on your garment and utilize the heat press for transfer. The cold peel method comes into play next, allowing the adhesive to cool before removing the film to reveal your finished product. Embracing this step-by-step process not only enhances your skills but also builds confidence as you master the art of DTF transfers.

Recent Innovations in DTF Printing

The DTF printing landscape is rapidly evolving, with recent innovations making it more accessible to a growing number of users. One significant advancement is the increasing availability of custom printing services aimed at hobbyists and entrepreneurs. Platforms now offer tailored DTF transfer services, allowing users to bypass the investments in equipment and directly order high-quality transfers suited to their designs. This change provides a hassle-free entry point for those who are just starting out in custom apparel printing.

Furthermore, commercial platforms specializing in DTF have recently emerged, streamlining the process for businesses looking to expand their offerings. These innovative services simplify purchasing and using DTF transfers, providing resources that assist crafters and small business owners in navigating the complexities of the printing industry. With these advancements, newcomers can now easily connect with quality services and resources that facilitate successful DTF printing ventures.

Caring for Your DTF Transfers: Dos and Don’ts

Once you’ve successfully created your custom DTF transfers and have applied them to your garments, proper care is crucial for maintaining their vibrancy and durability. Always follow specific care instructions, especially washing the fabric inside out to protect the prints from friction and fading. Cold wash cycles are recommended over hot water to minimize wear and tear, while air drying is preferable to prolong the life of the design and fabric.

Another important factor to consider is avoiding high-heat drying and ironing directly over the design. High temperatures can cause the prints to crack or peel, compromising the quality of your custom apparel. By following these dos and don’ts, you ensure that your DTF transfers maintain their fresh look for as long as possible, providing you with quality apparel that stands up to repeated use.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film which is then heat transferred onto garments. This process allows for vibrant colors and detailed imagery on various fabrics such as cotton and polyester, making DTF printing a versatile option for custom apparel.

What equipment do I need for DTF printing?

To get started with DTF printing, you’ll need a DTF printer that uses specialized inks, transfer film, adhesive powder, and a heat press machine. These are essential for printing, adhering, and transferring your designs onto garments effectively.

Can beginners easily learn how to use DTF transfers?

Yes, DTF printing is beginner-friendly! With a simple step-by-step process—from designing your artwork to applying the heat press—new users can quickly learn how to create vibrant DTF transfers and produce high-quality custom garments.

What are the advantages of using DTF printing for custom apparel?

DTF printing offers numerous advantages, including versatility across various fabrics, precision for intricate designs, vibrant colors, and no weeding requirement. This makes DTF transfers a popular choice for both hobbyists and professional printers.

How do I maintain the quality of my DTF transfers after application?

To preserve the quality of your DTF transfers, it’s important to follow care instructions: wash garments inside out in cold water, avoid high heat during drying, and do not iron directly on the printed area to maintain vibrancy.

Are there custom DTF printing services available for those who don’t want to invest in equipment?

Absolutely! Many companies now offer custom DTF printing services, allowing users to access high-quality prints without the need for personal equipment. This option is ideal for beginners looking to test the waters of custom apparel without significant upfront investment.

| Key Aspect | Details |

|---|---|

| What are DTF Transfers? | A printing method where designs are printed on a special film and then transferred onto garments using heat. |

| Advantages | 1. Versatility: Can be applied to various fabrics. 2. Precision: Captures intricate details. 3. Vibrant Colors: High-quality inks for vivid prints. 4. No Weeding: Saves time. |

| Equipment Needed | 1. DTF Printer 2. Transfer Film 3. Adhesive Powder 4. Heat Press Machine |

| Steps for Beginners | 1. Design Your Artwork 2. Prepare for Printing 3. Print the Design 4. Apply Adhesive Powder 5. Cure the Adhesive 6. Transfer to Fabric 7. Cold Peel 8. Follow Care Instructions |

| Recent Developments | 1. Custom Printing Services from companies like DesignBundles.net 2. Commercial DTF Platforms improving user experience for beginners |

Summary

DTF transfers offer an excellent introduction to the world of custom printing for beginners. This innovative printing method allows for vibrant, precise designs transferred onto various fabrics with ease. As the popularity of DTF transfers grows, the accessibility of related resources and equipment is improving, making it a fantastic choice for those interested in creative printing ventures. Embracing DTF transfers not only equips you with the skills to create unique apparel but also positions you well within a rapidly evolving market, offering tremendous potential for personal and commercial projects.